Reciprocating Mechanical Equipment and Electrical Control Systems are also referred to as Automation Electrical Equipment, they are essential in any industry for the purpose of enhancing efficiency and optimizing safety. With the evolution of technology such selecting the right equipment for a particular task seems effortless but it is quite tricky. This article is meant to provide insight to someone who is attempting to make a decision and wishes to choose an appropriate solution that will suit their needs.

Evaluating and Analysing Your Business Necessities

Before getting into the many types of automation electrical equipment, it is necessary to evaluate understanding your business needs first. One has to look at the kind of operations that are being conducted, what the size of the operations is and the specific components that need automating. This is essential as different industries have different needs for example manufacturers require larger machineries while smaller shops need smaller ones and so on. Getting an idea of your needs will provide you with an option to select from.

Certain Understanding of Automation Electrical Equipment

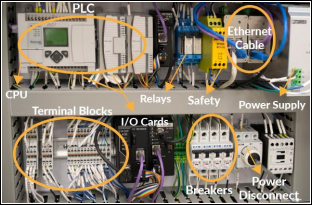

The scope of automation electrical equipment is rather broad as it includes PLC, sensors, actuators, motor drives etc. There is however a catch, each of them serves a different purpose. For instance, one can deem processes controlled by Programmable Logic Controllers as critical, whilst, changes in the environment are detected and acted upon by sensors and actuators, respectively. Thus, by understanding the broad scope automation have and the functions each serve, this will aid you in attaining the right equipment for your business operations.

Assess Quality and Dependability

When choosing electrical automation equipment quality and reliability comes first. High-quality equipment doesn’t only extend a client’s lifetime but also saves on downtime. Investigate well-known manufacturers with solid products and good service to support them. Reviews and suggestions from colleagues within the industry may assist in establishing the credibility of particular brands and models.

The Economics of the Situation

It would be wise to exercise common sense as there is a strong urge to use the most affordable options for most non-repair stage tools. Think in terms of the total cost of ownership instead of the acquisition cost alone. These include installing, maintaining, and operating the system. While equipment may be expensive whenever it is purchased at the start, it may lead to tremendous savings later due to having to maintain the equipment less and more efficient utilization. Use a cost benefit approach in deciding what best serves the purposes of your organization.

Ensuring Your Investment is Future-Proof

The pace at which technology is advancing means that your automation electrical equipment should be able to stand the test of time. Automating specific technologies is a simple method to future-proof a device, such devices should be widespread in your search. This degree of flexibility will make it so that as your operations change, your invested asset will remain relevant and functional. Also, look for devices that allow software updates and have strong or the manufacturer’s communities with which you can keep pace with the latest trends and insights in your field.

Trends and Insights

With the advancement of industries, associated German technologies related to automation electrical equipments also advance. Moreover, among the current trends in the market, there is the growing integration with IoT, which makes operations smarter and enables data analysis in real time. In addition, AI (artificial intelligence) is expected to greatly improve the performance of automatic systems in the near future. Following those trends closely will notify you on when to make neat choices when buying the equipment; ones that will do more than tick the boxes of current demand requirements.